Plate & Cube Beam Splitters

Plate beam splitters consist of a thin plate of optical glass with a different type of thin film coating on each side. The first surface is coated with an all-dielectric film having partial reflection properties over either the visible or the near-infrared spectrum. The benefit of this type of coating is that it has low absorption, typically 0.5 percent for a 50/50 splitter at 45°.

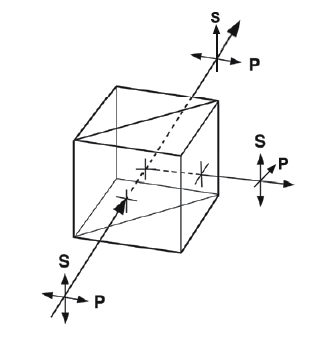

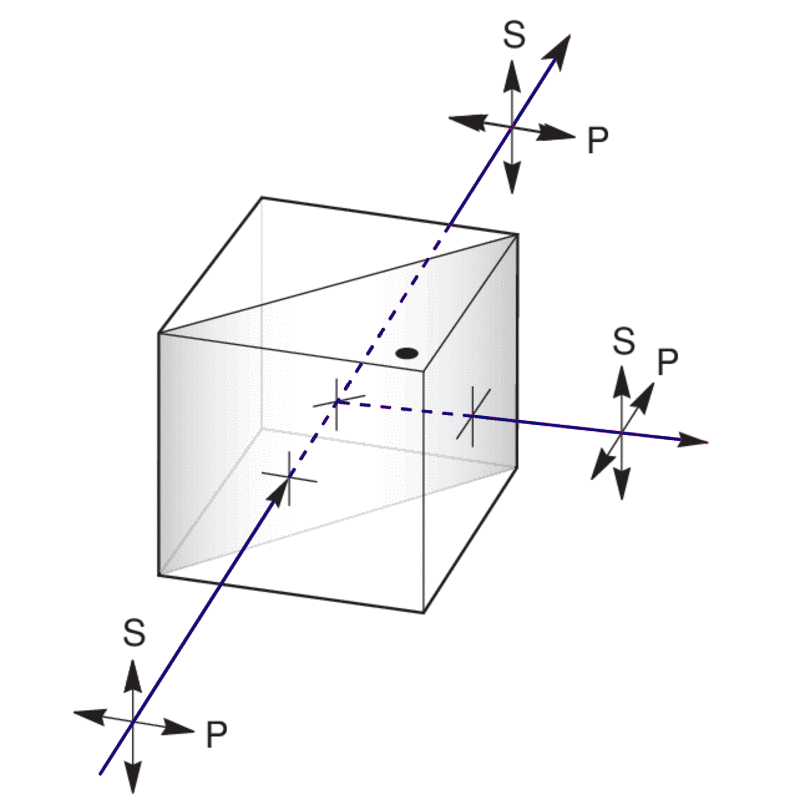

Cube beam splitters consist of two identical right-angle prisms with their hypotenuse faces cemented together. Prior to cementing, a partial reflection film is deposited onto one of the faces. For best results, the incident beam should be on one of the faces of this prism. For better performance cube beams plitters should be antireflection-coated on all four faces to minimize ghost images.

Cube beam splitter have several advantages over plate beam splitters and are widely used for a variety of reasons. Cube beam splitter deforms much less when Compare to plate Beam splitter . Most of the unwanted reflections from a cube beam splitter are in the retro direction and do not contribute to ghost images. The coating is very resistant to degradation with time because it is concealed in between prisms of the cube.

Types of Beamsplitter and Selection Guide

Selection Criteria :

- Polarizing or non-polarizing

- Non-polarizing beam Splitting ratio (examples may be 50-50, 70-30, 90-10)

- Separating Wavelength

- Power handling (high power or high incident laser energy)

- Beam displacement tolerance

- Cube or plate Beam splitter

Specification | Plate | Cube |

|---|---|---|

Wavelength |

|

|

Dimensions |

|

|

Beam splitting Ratio |

|

|

Coating types |

|

|

Non Polarizing Cube Beam Splitter

Specification | Grade |

|---|---|

Material | BK7 |

Diameter | 10mm To Maximum |

Clear Aperture | >80% |

Flatness | < λ / 4 @ 633 nm |

Beam Deviation | <3 arc minutes |

Chamfer | Protected <0.5mm*45` |

Peak Transmission | >45% |

Polarization | <6% |

Coating | AR Coating |

A beam splitter is used to split a beam of incident light in two. Our optical beam splitters are made from high-grade glass materials with laser grade surface flatness and surface quality for tighter tolerance on the beam splitting ratio.

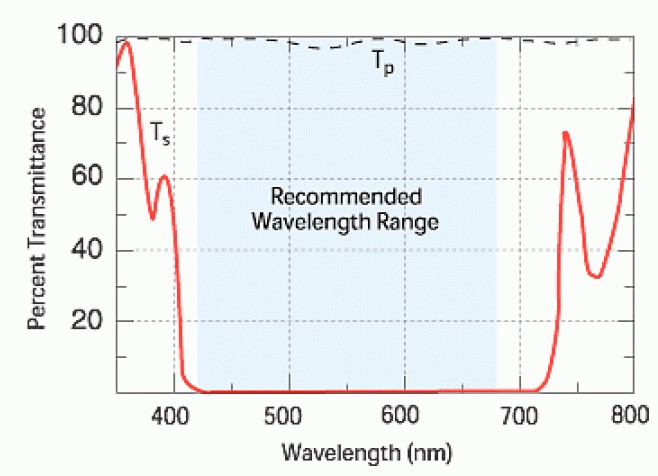

Beam Splitter: Broadband

Diameter: Laser beam manipulation, life science instrumentation

Material: BK7

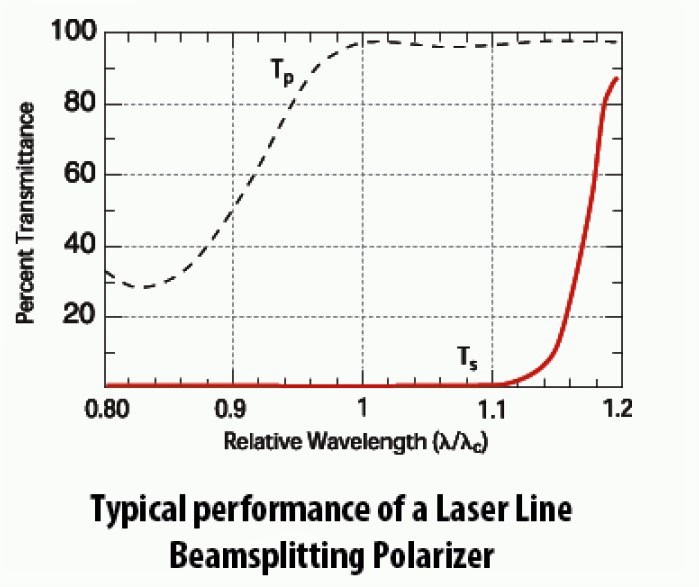

Filter: Laserline

Diameter: Low power applications

Material: BK7

Dimension | Material | Reflection / Transmission % | Wavelength Range | Beam Deviation | Surface Flatness |

|---|---|---|---|---|---|

12.5mm x 12.5mm x 12.5mm +/-0.1 | BK7 | 30/70 ; 70/30 ; 50/50 | 400-700 nm | 5 arc min | Lambda/4 |

20mm x 20mm x 20mm +/-0.1 | BK7 | 30/70 ; 70/30 ; 50/50 | 400-700 nm | 5 arc min | Lambda/4 |

25mm x 25mm x 25mm +/-0.1 | BK7 | 30/70 ; 70/30 ; 50/50 | 400-700 nm | 5 arc min | Lambda/4 |

37.5mm x 37.5mm x 37.5mm +/-0.1 | BK7 | 30/70 ; 70/30 ; 50/50 | 400-700 nm | 5 arc min | Lambda/4 |

50mm x 50mm x 50mm +/-0.1 | BK7 | 30/70 ; 70/30 ; 50/50 | 400-700 nm | 5 arc min | Lambda/4 |

Polarizing Cube Beam Splitter

A beam splitter is used to split a beam of incident light in two. Our optical beam splitters are made from high-grade glass materials with laser grade surface flatness and surface quality for tighter tolerance on the beam splitting ratio.

Specification | Grade |

|---|---|

Substrate | BK7 |

Dimensional Tolerance | ± 0.010″ |

Angle of Reflectance | 90° |

Clear Aperture | >80% |

Beam Deviation | < 3 minutes |

Transmission of p-polarization | Tave > 90% |

Reflectance of s-polarization | Rave > 99.8% |

Peak Transmission | >45% |

Clear Aperture | > 85% |

Beam Splitter: Broadband

Diameter: These Lenses Have Considerably Reduced Values Of Spherical Aberrations. Best Used To Replace Single Components Where Performance Must Be Improved.

Material: Combinations Of Two Optical Grade Glasses

Filter: Laserline

Diameter: Used In Pulsed Laser Systems For Purifying The Polarization State In Multimode Lasers.

Material: BK7

We are a pioneer in the manufacturing of Precision Optics such as Optical Lenses, Optical Filters, Optical Mirrors, Optical Prisms, Optical Window, Beam Splitter, Thin Film Coating, and Opto-Mechanical Products & Systems. Get a Quick Quote now!